Thermal Spray

The Thermal Spray Group at University West is the only one of its kind within the academic environment in Sweden. The technology is typically used to deposit coatings for life-extension of components or to impart special functions on their surface. The group works with numerous industrial partners and is internationally well-recognized.

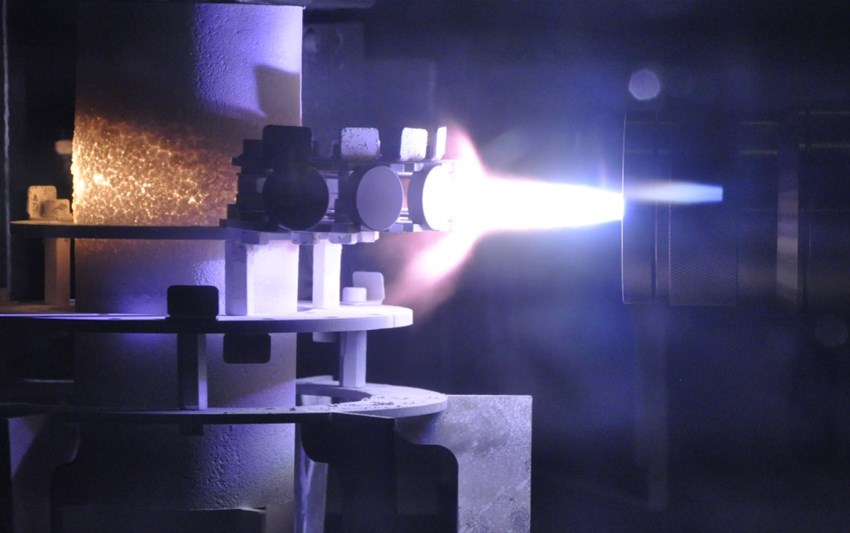

Thermal spraying is a process wherein a material, traditionally fed in the form of a powder, is heated to a molten or semi-molten state in a high-temperature high-velocity zone and the resulting particle or droplet is propelled onto the surface to be coated. The range of materials that can be deposited include metals, alloys, ceramics, plastics, and composites, and can be built up in the thickness range of 20 microns to several mm over a large area and at a high deposition rates.

The unique spray facilities available in the group comprise an axial feed capable plasma spray system and a high-velocity air-fuel (HVAF) unit that enable the most appropriate thermal spray route to be adopted depending on the material to be coated. Due to the huge spread of materials that can be sprayed, the coating properties can be tailored to meet the functional requirements of a wide spectrum of applications relevant to gas turbines, diesel engines, bearings, journals, pumps, compressors etc. as well as key components required in oil & gas, steel, pulp & paper industries.

News articles

Thematic leader - Thermal Spray